Disc Type Couplings Guide: Types, Uses & Advantages

Precision and reliability define successful modern industrial systems. Within these operations, power transmission components like couplings are crucial for the seamless performance of rotating equipment. Among various coupling solutions, disc type couplings stand out for their exceptional accuracy, durability, and capability in demanding applications.

From pumps and compressors to turbines and power transmission systems, disc couplings are widely used across industries. This guide explores what disc type couplings are, their types, applications, and the advantages of disc couplings, along with tips on choosing the right one for your machinery.

What are Disc Type Couplings?

Definition & Core Components of Disc type couplings

A disc coupling is a flexible coupling that transmits torque between two shafts while accommodating misalignment. It consists of thin, flexible metallic discs that deform slightly under load, allowing the shafts to stay connected without compromising performance.

How Disc type couplings work

The key feature of disc couplings lies in their ability to flex. The metal discs bend to absorb misalignment—whether angular, parallel, or axial—while still maintaining high torque transmission. Unlike gear couplings, they do not require lubrication, making them a cleaner, more efficient solution for many industries.

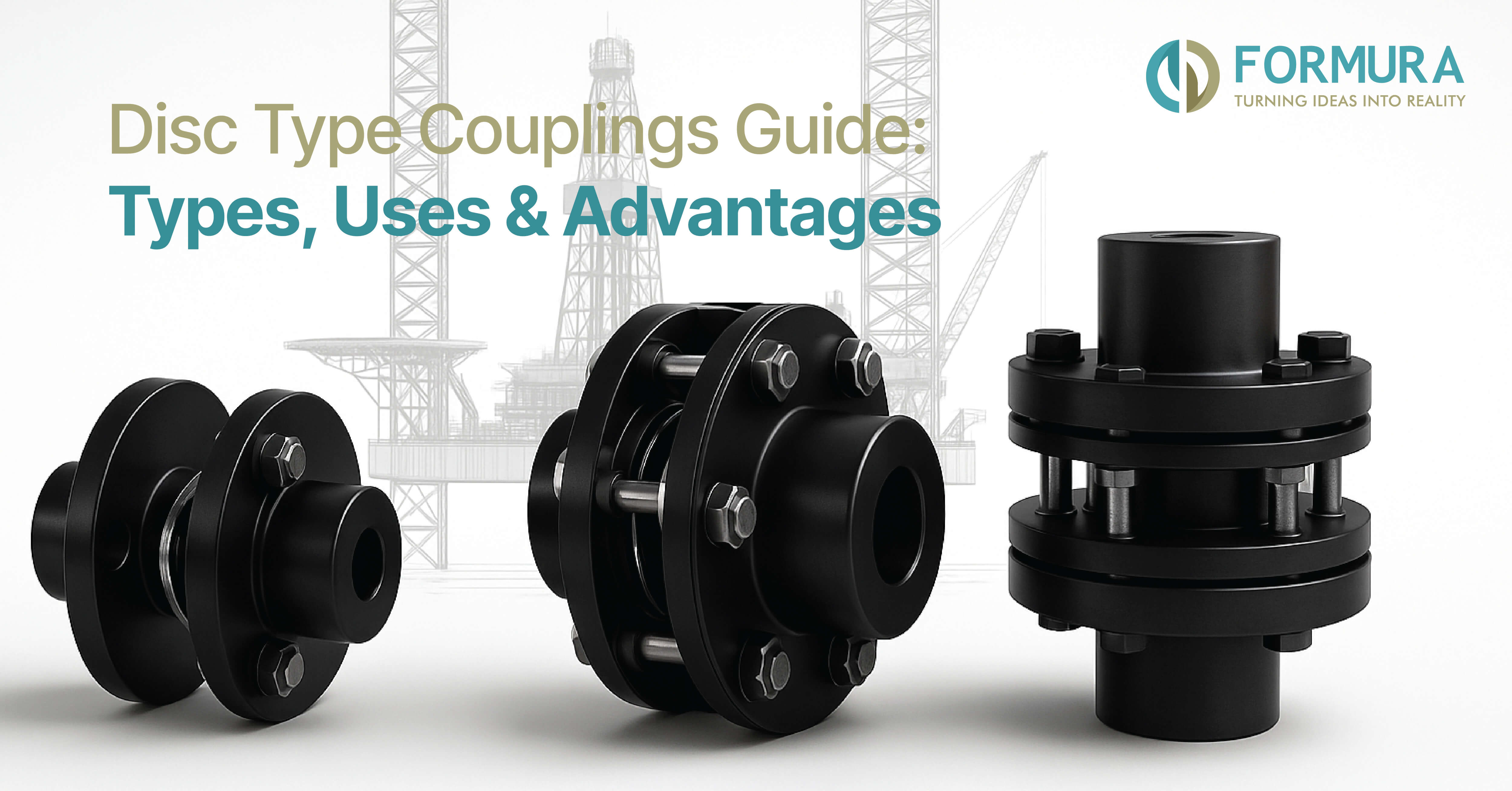

Types of Disc Type Couplings

Based on Formura’s product range, the main disc coupling types include:

1. Single Disc Couplings

Designed for applications with limited misalignment and shorter shaft distances. They are compact, lightweight, and ideal for precision equipment.

2. Double Disc Couplings

These couplings feature two sets of disc packs with a spacer in between, allowing them to handle greater misalignment and longer shaft separations.

3. Spacer Disc Couplings

A variation of the double disc design, spacer couplings are used where shafts are far apart or where accessibility for maintenance is required.

Explore our Disc type couplings product range including;

- DPU Series

- DMU Series

- DMUCC Series

- DLC Series

- High speed series

- DWMO series

- Trummy low & middle speed series

- Trummy high speed series

Each type serves unique operational needs, and working with trusted disc coupling manufacturers and industrial coupling suppliers ensures the right fit for your application.

Key Applications & Uses of Disc Type Couplings

Disc type couplings are versatile and used across multiple sectors. Some of the most common applications of disc couplings include:

- Manufacturing Machinery – Conveyors, mixers, and machine tools require precise torque transfer and misalignment handling.

- Power Transmission Systems – Critical for motors, drives, and generators where reliability is essential.

- Pumps, Compressors, and Turbines – Disc couplings handle continuous operation in pumps and compressors, especially in oil & gas and chemical industries.

- Energy & Power Plants – Gas turbines, steam turbines, and alternators rely on disc couplings for smooth operation.

- Marine Applications – Used in propulsion systems, where reliability under harsh conditions is crucial.

Also Read : Top Coupling Mistakes and Ways to Prevent & Correct Them What Are Industrial Couplings? Types, Uses, and Benefits

Advantages of Disc Type Couplings

The advantages of disc couplings are numerous, making them a preferred choice across industries:

1. High Torque Capacity

Disc couplings are capable of transmitting very high torque without compromising on performance, making them suitable for heavy duty applications.

2. Zero Backlash Operation

Unlike other couplings, disc couplings provide precise, backlash-free torque transmission. This makes them ideal for servo drives and automation systems.

3. Low Maintenance Needs

Since they are non-lubricated, disc couplings require minimal upkeep compared to gear couplings. This reduces downtime and operational costs.

4. Durability & Reliability

Made of stainless steel or high-strength alloys, disc couplings withstand harsh environments and continuous duty cycles, ensuring long service life.

5. Misalignment Tolerance

They can handle angular, parallel, and axial misalignments while maintaining efficiency.

Factors to Consider Before Choosing Disc Type Couplings

Selecting the right disc coupling depends on multiple factors. Here’s what industries must evaluate:

- Operating Environment – Consider temperature, presence of corrosive materials, and exposure to moisture.

- Torque Requirements – Match the torque capacity of the coupling with your machinery’s operational needs.

- Misalignment Tolerance – Assess the degree of angular, parallel, or axial misalignment in your system.

- Speed & Vibration Levels – Ensure the coupling can operate at your equipment’s required speed without causing imbalance.

- Space Constraints – Choose between single, double, or spacer disc couplings based on available installation space.

Consulting with expert coupling suppliers, gear coupling dealers, or disc coupling manufacturers ensures you make the right choice for your system.

Installation & Maintenance Tips of Disc Type Couplings

Even the highest-quality coupling may not perform to its full potential if it is not installed and maintained properly. Consider the following recommendations:

- Ensure Proper Alignment: While disc couplings can handle misalignment, precision alignment reduces stress and prolongs life.

- Follow Manufacturer Guidelines: Torque values, tightening sequences, and disc pack assembly must follow the instructions provided by the supplier.

- Routine Inspections: Check for wear, fatigue cracks, and unusual vibrations.

- Avoid Overloading: Never exceed torque or speed ratings to prevent premature failure.

- Partner with Experts: Reliable industrial coupling suppliers and disc type coupling manufacturers can provide technical support and spare parts when required.

Conclusion

Disc type couplings combine strength, flexibility, and precision, making them one of the most trusted coupling solutions in modern industries. Their ability to transmit high torque, operate backlash-free, and require low maintenance sets them apart from other coupling designs.

By understanding the disc coupling types, evaluating operational requirements, and working closely with expert coupling suppliers, product sellers, and gear coupling dealers, industries can achieve longer machinery life, improved efficiency, and reduced downtime.

At Formura, we specialize in providing high-quality disc type couplings designed to meet the needs of diverse industries. As one of the trusted manufacturers of disc couplings, gear couplings, and industrial couplings, we not only deliver reliable products but also help you choose and maintain the right solutions for your machinery.

Contact our experts now for tailored advice or immediate problem-solving to keep your operations efficient and reliable.