Engineering Excellence: How Formura Rescued Critical Leg Integrity

Introduction: The Challenge

A critical offshore drilling asset, was facing a severe operational threat. During routine inspections, significant wear and damage were discovered across its entire jacking system—the essential machinery that allows the rig to raise and lower its legs for positioning and stability. With issues identified in all three legs (Forward, Starboard, and Port), the rig's operational readiness and safety were compromised. Needed a rapid, reliable, and comprehensive repair solution to avoid extensive, costly downtime and ensure the vessel could return to service safely and on schedule.

Project Scope & Objectives

Formura Offshore Services was tasked with a massive, complex overhaul for jacking system. The project scope was extensive, covering multiple drive systems across all three legs.

The primary objectives were:

- Comprehensive Inspection: Conduct a thorough assessment of all Primary, Secondary, and Final Drive units on the FWD, STBD, and PORT legs.

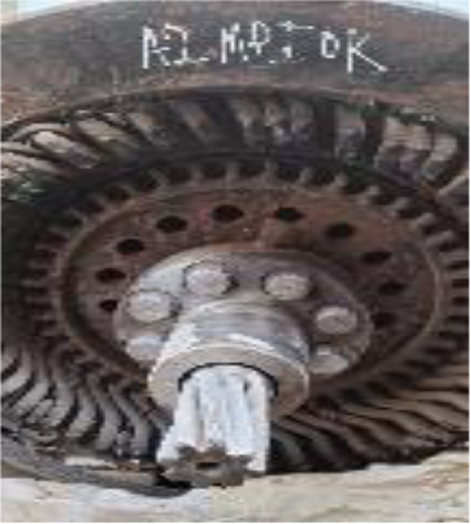

- Systematic Repair & Replacement: Dismantle, inspect, and repair damaged components including gears, pinions, output shafts, and hub assemblies.

- Ensure Integrity: Replace all severely worn or damaged parts with new or NDT-approved components to restore full structural and operational integrity.

- Prevent Future Failure: Replace all seals, bearings, and fasteners as a standard practice to ensure long-term reliability and prevent oil leaks and mechanical failures.

The project involved a meticulous repair process on 29 individual units, demonstrating the scale and complexity of the undertaking.

Key Challenges & Solutions

Formura's team encountered several significant challenges, which were overcome with technical expertise and a methodical approach.

| Challenge | Formura's Solution |

|---|---|

| Widespread & Severe Damage: Components across all legs showed critical failures, including severe pitting, spalling, twisted splines, and major cracks (e.g., a 44mm warpage on Unit K3). | Systematic Component Management: Each unit was meticulously dismantled and inspected. Parts were repaired, replaced with new ones, or re-used only after passing rigorous Non-Destructive Testing (MPI/NDT), ensuring all installed components met original equipment standards. |

| Complexity of Multiple Systems: The project involved three different drive systems (Primary, Secondary, Final), each with unique components and tolerances. | Specialized Technical Expertise: Formura's engineers demonstrated deep knowledge of jacking system mechanics, correctly diagnosing issues like excessive uplift and warpage, and executing precise repairs specific to each system's requirements. |

| Ensuring Long-Term Reliability: Simply fixing the immediate damage risked future failures shortly after the rig returned to service. | Proactive Overhaul Philosophy: Beyond just the damaged parts, Formura proactively replaced all associated seals, bearings, and fasteners during reassembly. This comprehensive approach guaranteed a robust repair that extended the system's operational life. |

| Adherence to Tight Timelines: The 24-day project window demanded high efficiency to minimize the client's downtime. | Efficient Execution: The experienced service team worked systematically across all 29 units, managing the workflow efficiently to complete the extensive scope within the scheduled timeframe. |

Project Results & Conclusion

Formura Offshore Services successfully executed one of the most comprehensive jacking system overhauls on the rig. The project was completed on schedule, from May 16 to June 8, 2023.

Key Results:

- Restored Operational Integrity: All 29 units across the three legs were repaired, reassembled, and restored to full working condition.

- Safety & Compliance Assured: The rigorous use of NDT and replacement of critical components guaranteed the jacking system's safety and compliance with operational standards.

- Downtime Minimized: The efficient execution allowed to return to its drilling operations with minimal delay, saving the client from significant financial losses.

- Future-Proofed Performance: The proactive replacement of wear-and-tear items (seals, bearings) ensured enhanced reliability and reduced the risk of near-term future breakdowns.

Conclusion

This project stands as a testament to Formura Offshore Services' capability to handle large-scale, complex offshore repair challenges. Faced with extensive damage to a critical system, Formura delivered a solution that was not only technically superb but also managed with a focus on the client's operational and financial priorities. The successful restoration of jacking system underscores Formura's position as a trusted partner for ensuring the safety, reliability, and longevity of offshore assets.