ESCO Flexible Coupling Solution

Introduction: Application Details

- Machine: Wire Drawing / Wire Rope Equipment

- Drive System: Motor – Gearbox – Machine Shaft

- Control System: VFD-based operation

Challenges: Problem Statement

Customer was using locally manufactured couplings in their machines. Over time, they faced repeated issues related to:

- Improper coupling fitment

- Radial and axial misalignment

- Shaft bore and keyway tolerance variation

- Excessive axial movement during operation

The observed shaft bore size was 106.4 mm, and due to DBSE and misalignment, the coupling performance was unsatisfactory.

Initial Engagement & Technical Study

- Site visit conducted for enquiry and application understanding

- Initial offer submitted for FST 110 & EPB 178, however the offer was closed due to pricing

- Second site visit conducted

- Local make 106 size coupling found installed

- Customer reported fitment and alignment problems

- VFD system impact considered during analysis

Proposed Solution (Solutions)

Based on detailed technical evaluation, ESCO Flexible Gear Couplings were recommended due to their:

- High misalignment capacity

- Robust design suitable for VFD applications

- Reliable performance under variable loads

Recommended Models:

- FST 110

- FST 130

- EPB 178

Order & Execution Timeline

- Revised enquiry received; offers submitted for FST 110, FST 130, EPB 162 & EPB 178

- Order finalized and material dispatched

- Alignment visit planned

- Joint visit with technical team for installation and issue analysis

Installation & Observation

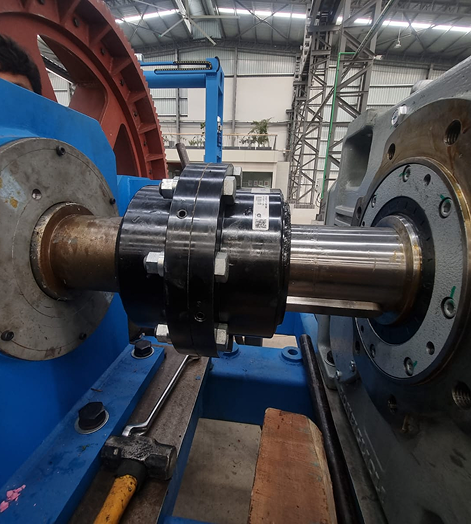

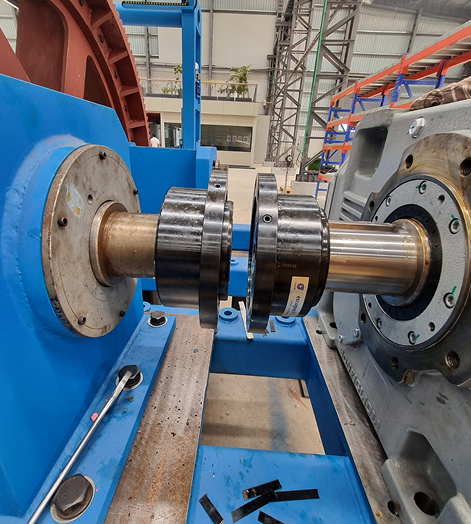

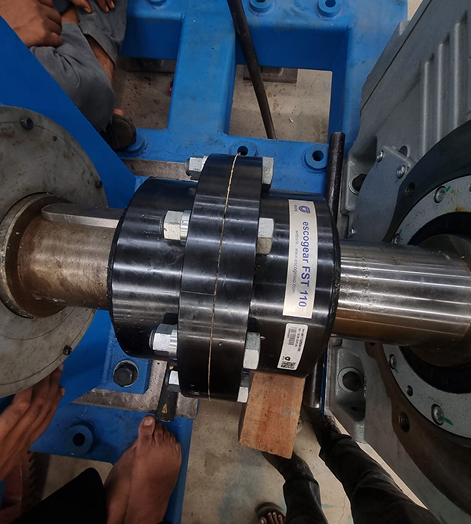

During installation of FST 110 Gear Coupling between gearbox and machine shaft:

- Alignment was checked between:

- Motor to Gearbox

- Gearbox to Machine

- Axial movement of approx. 8 mm was observed in:

- Machine–Gearbox connection

- Gearbox–Motor connection

Root Cause Identified:

Shaft tolerance was found to be in minus, resulting in loose fitment after installation.

Corrective Actions Taken

- Guided customer on proper drilling and tapping procedure

- Ensured adequate lubrication before installation

- Provided on-site technical guidance to stabilize coupling fitment

- Recommended maintaining shaft tolerance in plus for future machines

Project Results & Outcome, Conclusion

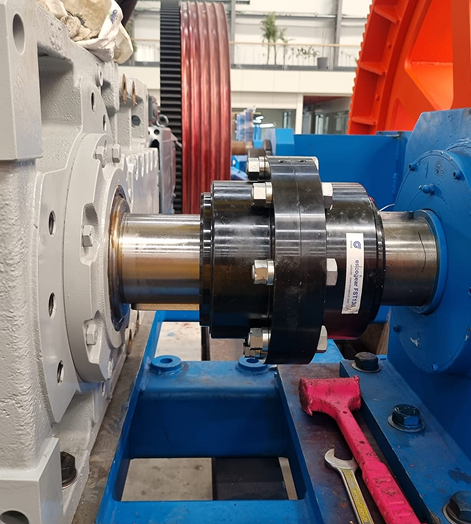

- Coupling fitment issue resolved successfully

- Smooth operation achieved after corrective actions

- Customer highly satisfied with ESCO’s technical support

Repeat Order Received:

- Repeat order for FST 110, FST 130 & EPB 178

- Successful installation completed

Visuals of Projects

- Drilling and tapping process

- Lubrication before installation

- FST 130 installed

- EPB 178 installed

- Axial movement observation (~8 mm)

Customer Confidence & Future Business

Based on technical performance and service support:

- Customer has standardized ESCO couplings for their machines

- New enquiry received for:

- EPB 198

- FST 155

- FST 110

ESCO is now the preferred coupling solution provider to customer.